Our railway solutions

Applications of our composite materials and components in the interior and exterior of rail vehicles:

- Exterior panelling

- Interior panelling

- Partition walls, side walls, and room dividers

- Flexible panels, gangways, and passageways

- Floor plates, floor systems, and floor channel systems

- Luggage racks and hat shelves

- Seats, armrests, and serving tables

- Flaps, covers, and hoods

- Window frames

- Door systems

- Ceiling panels and ceiling systems

- Roof skirts, roof structures, and roof systems

- Antenna radomes and telecommunications technology

In the field of rail transportation technology, Krempel has been a leading provider of certified composite materials and components tailored to the demanding requirements of rail transport for many decades. The range is comprehensive and versatile, including prepregs, pultrusion profiles, technical laminates, films, and complex structures and components. We have a solution ready for all applications in interior or exterior settings.

Composite materials, particularly those composed of a combination of different materials, play a crucial role in manufacturing components such as claddings, structural elements, floorings, seats, and other parts in trains and railways. Composite materials are durable and robust, ensuring reliable performance throughout the entire lifespan of the rail vehicle. Even under the most challenging mechanical, thermal, and chemical stresses, composite materials withstand the test of time.

For the support structures of trains, composite materials are essential as they are strong and lightweight simultaneously, increasing the efficiency and extending the lifespan of trains.

All our products meet the highest Fire, Smoke, and Toxicity (FST) fire protection requirements according to EN 45545.

However, we not only meet standards but also set new ones, as demonstrated by our recent composite material innovation, KremGuard.

Our experts specializing in plastic and material technology develop specific and cost-effective solutions for your individual requirements. As your partner, we accompany you through all project stages, from the development phase to series production, drawing on our experience and expertise from numerous rail projects.

Our railway portfolio

- Prepregs based on epoxy and phenolic resins for the highest fire protection classes

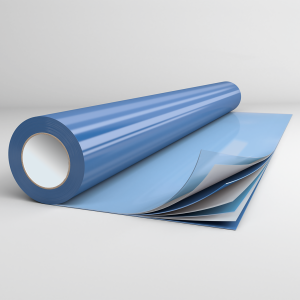

- fiberglass-reinforced plastic (FRP) sheets based on phenolic, epoxy, and polycarbonate glass

- FRP components, molded parts, sandwich structures, and complex assemblies ideal for interior applications in walls, ceilings, floors, and transitions

- Thermoplastic organosheets

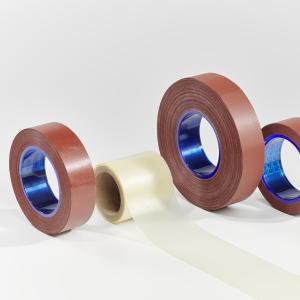

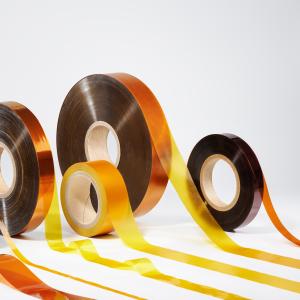

- Multilayer laminates, decorative films, Tedlar® polyvinyl fluoride films, and Kapton® polyimide films specially suitable for coatings and graffiti prevention

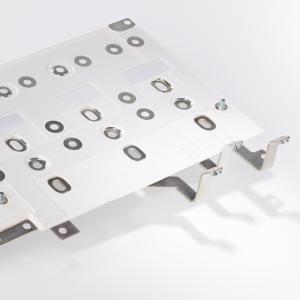

- Pultrusion profiles such as corner profiles for window frames

- Antenna radomes for telecommunications and radar technology

- Composite tubes

- Electrical insulation for motors and generators

- Processing of thermoplastic and thermosetting materials using autoclaves, ovens, injection molding, and molding machines

- Machining, finishing, and assembly using 5-axis milling machines and water jet cutting systems

- Comprehensive solutions from a single source

Rail-certified quality & expertise

Safety is the top priority in rail transport technology. With composite materials and components from Krempel, you are on the safe side. Our entire portfolio adheres to the strictest safety and quality standards and is certified according to the rail standard EN 45545 HL3, R1, R7, R17.

We collaborate closely with testing laboratories to ensure the certification and qualification of our products according to EN 45545. This standard ensures top-notch Fire, Smoke, and Toxicity (FST) fire protection properties to safeguard passengers and personnel in the event of an unintended fire.

In managing and executing your projects, we adhere to the high standards of rail technology, ensuring the utmost care, optimal process reliability, and seamless traceability of all parts.

Composites materials for railway applications

You can have confidence in this:

-

FST fire protection and certified safety: Adherence to the highest fire protection classes and standards: EN 45545 HL3, R1, R7, R17.

-

Weight reduction: Compared to traditional materials, composite materials are lighter, leading to a reduction in the overall weight of rail vehicles. A lower mass results in less energy consumption and lower operating costs.

-

Strength and durability: Composite materials exhibit high strength and durability, contributing to a longer lifespan of components. They are resistant to mechanical stresses, easy to maintain, and withstand environmental factors such as corrosion and UV radiation.

-

Functionality and design: The combination of different materials allows for the targeted achievement of specific properties, such as fire protection, sound insulation, heat resistance, or vibration damping, without compromising on aesthetic design.

Railway applications of our materials and components:

- High-speed and Intercity trains

- Local and regional trains

- Subways and metros

- Trams and light rail systems

- People Mover

- Monorails

- Locomotives

- Gondolas

Innovation KremGuard

KremGuard, our latest innovation for mobile applications, is an epoxy resin-based prepreg system that meets the highest Fire, Smoke, and Toxicity (FST) fire protection requirements. It also offers excellent mechanical properties and is free from phenol, formaldehyde, and halogens. A groundbreaking innovation that opens up new possibilities in rail technology.

Downloads

KremGuard - Fire and Flame Safety

Epoxy prepreg system for maximum fire protection

E-Mobility

High-performance materials for electric vehicles